FOCAS Heavy

Hoeing machine FOCAS Heavy

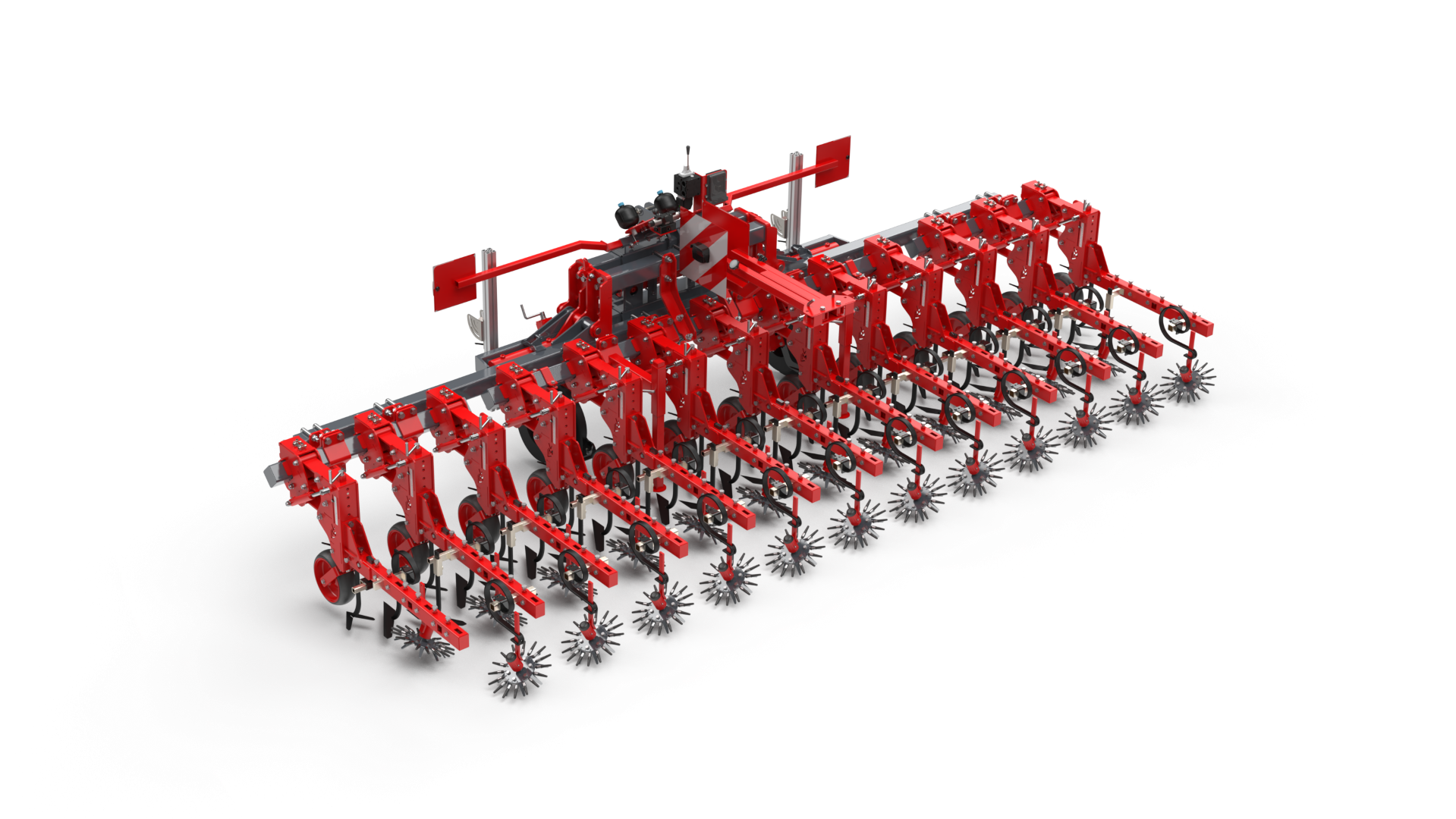

The FOCAS Heavy is a camera-controlled hoeing machine with the most solid chassis in our range. It combines precision and heavy-duty capability through a patented parallel system. Thanks to its high-tech and ultra-precise camera, the FOCAS Heavy hoes very close to the crop. As soon as the young crop emerges above the ground, you perform various operations without damage.

No clearance, only stability and precision

The FOCAS Heavy is the most robust and strongest hoeing machine in our range. Various elements on the machine ensure that there is no clearance. This has two enormous advantages:

- The FOCAS Heavy hoes very close to the crop

- The hoeing machine works extremely precisely and makes manual work virtually unnecessary

The main components of the FOCAS Heavy that ensure the reliable stability of the machine are:

1. Compact shifting system

With a built-in sideshift on polymer guidance, the FOCAS Heavy system is extremely compact. This means the hoeing elements are very close to the tractor. This results in a machine which works very accurately and in a controlled manner.

It is also a system which requires little to no maintenance. Unlike a guide with bearings, you do not need to lubricate a plastic system. An additional advantage is dust caused by hoeing cannot stick and will therefore wear out the parts less quickly.

An additional advantage of our system is the proportional control. This means the machine automatically adjusts the reaction speed of the sideshift based on its location: slow near the crops, fast when the distance from the crops is greater. This is possible thanks to the smart camera guidance and the fine control capabilities of the hydraulics.

The results proves the machine is very precise. Several tests shows the FOCAS Heavy is accurate to less than 10 mm. In other words: the machine works very close to the plant, allowing you to weed more weeds and increase the competitive advantage of the crop over the weeds.

2. Adjustable support wheels

The support wheels ensure the stability of the FOCAS Heavy. These have a disc with a diameter of 60 cm which goes 10 cm into the ground and ensures the tractor is not influenced by the movements of the hoeing machine. In other words: the machine runs more stable behind the tractor.

These wheels are adjustable in height and width, and the composition of the wheel can also be easily adjusted. The support wheel is standard equipped with 2 metal wheels with a disc in between. For example, you can remove one of the metal wheels to enable narrower driving distances.

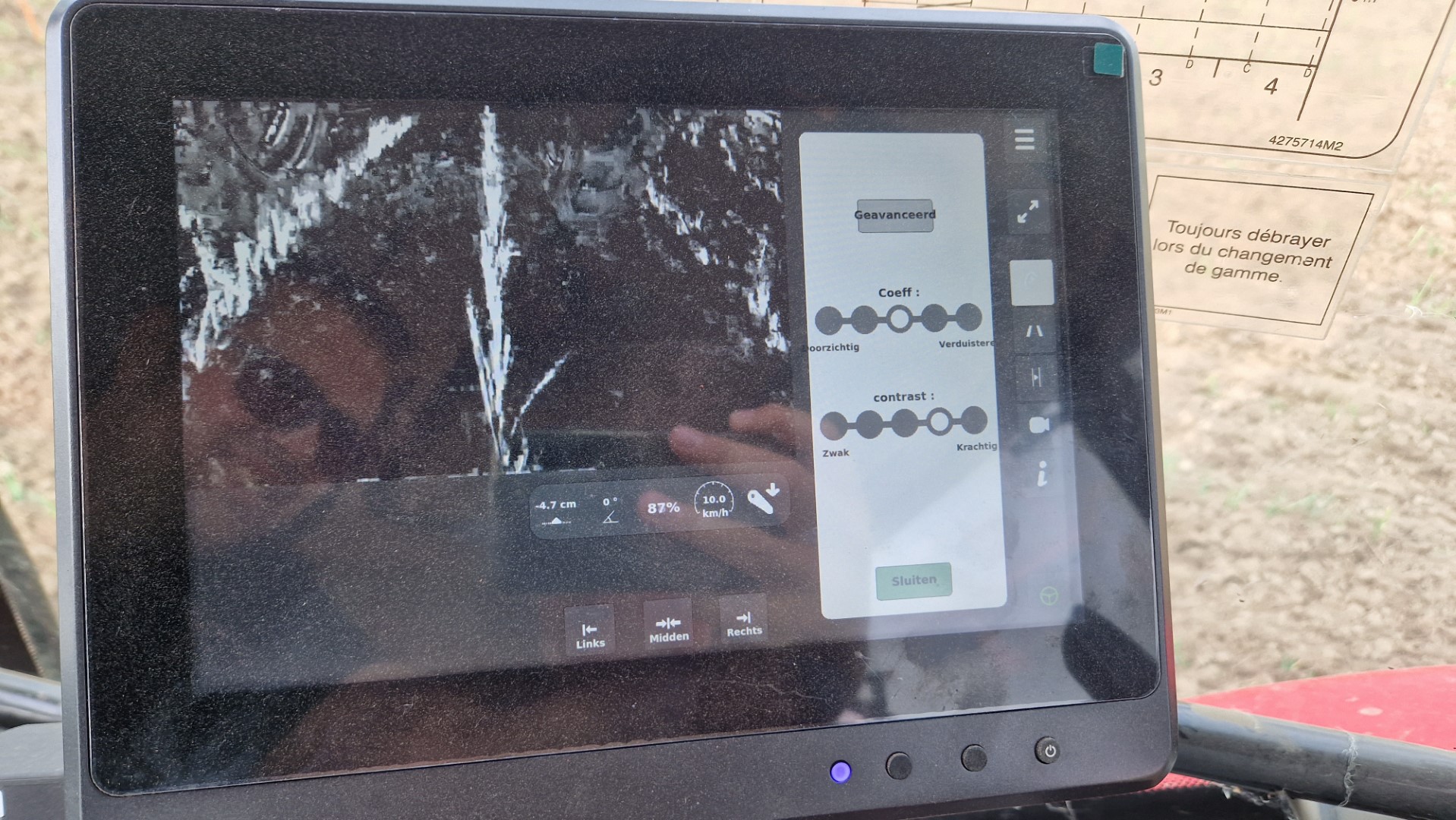

3. Camera control

Since the camera was developed according to the latest technologies and innovations, it is very easy to use. The interface is developed by people from the agricultural sector, who understand what is important for people on the field and translate this to a user-friendly system. In other words: you have very little setup work, the camera does a lot automatically, the system is very clear and therefore user-friendly.

Furthermore, the camera uses an autofocus system. They also automatically adjust to the light intensity of daylight. Thanks to the autofocus, the camera sees the crops precisely and regardless of the amount of sunlight.

When setting up the camera, you choose the number of rows and the row distance that the camera should follow. These parameters are projected onto the observed image and then a score is assigned. The closer the set lines are to the observed lines, the higher the score. This score has an adjustable threshold value. Below this value the hoeing machine remains static, above this value the hoeing machine moves again. So, if there is a place in the row where there is no crop, the machine will not “search” and thus avoid hoeing away several rows.

The camera control is continuously improved through over-the-air updates. An example of such an update is automatically calculating the angle and height of the camera according to the set rows + row distance.

If you only use GPS guidance, you are more likely to have deviations. Several factors contribute to this. Especially if the crop was sown or planted with another GPS system, the chance of deviations is very high. This can be up to 4cm, making accurate hoeing impossible. A camera guidance system works perfectly with a GPS-controlled tractor. The camera guidance software automatically compensates for the deviation of the GPS because the actual plant row is followed. This is how precision hoeing is achieved.

4. Double beams

The chassis of the machine consists of two beams: one is positioned flat and the second is at an angle of 45°. Machines wider than 3 meters are available in a folding version.

The beams are connected to each other with movable clamps, so that any row distances can be chosen. It provides a modular system and makes the machine stronger and more stable at the same time.

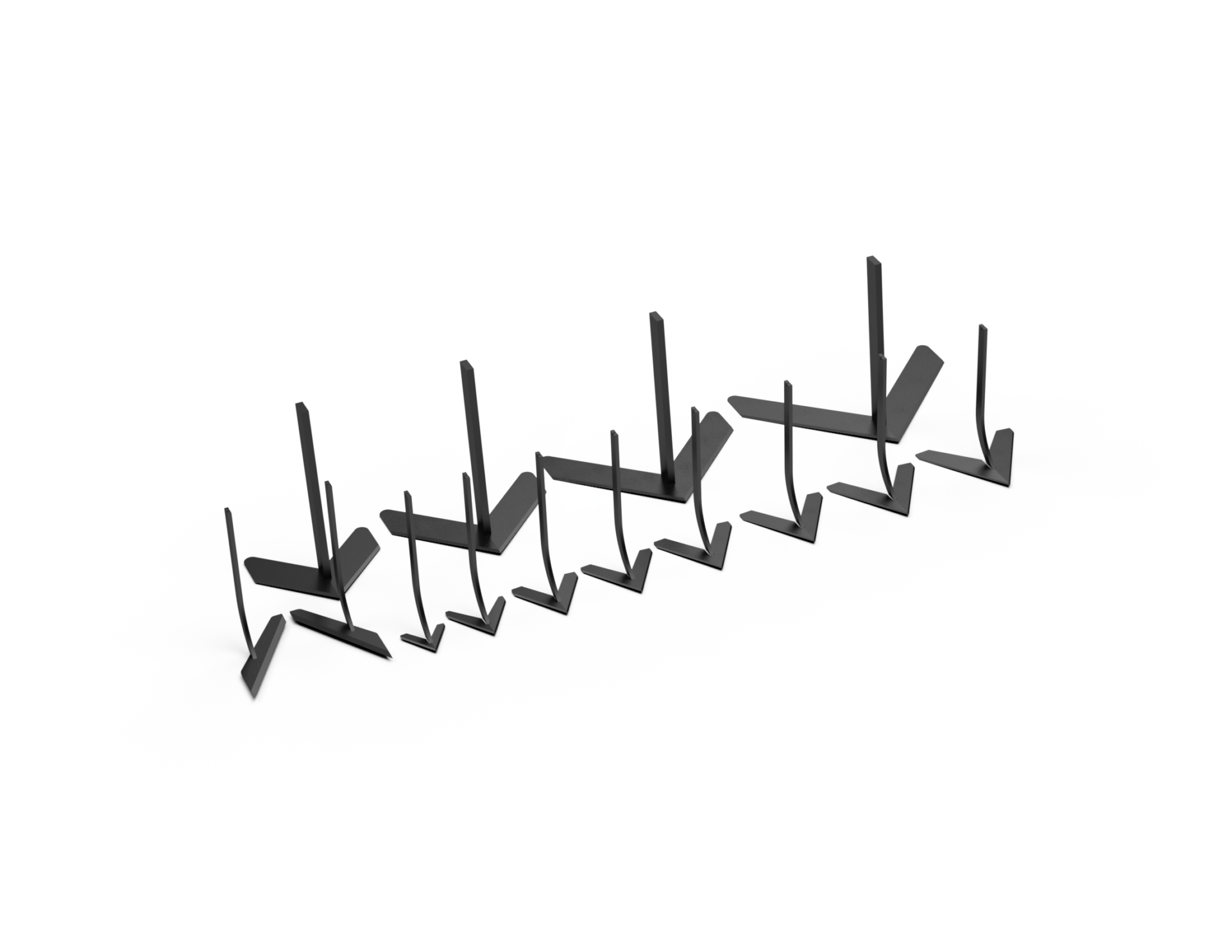

5. Patented parallel system

Very simple but revolutionary. That is the least you can say about our parallel system. By adding an extra connecting element which is not in line with the other connecting elements, we process the lateral forces more efficiently. This drastically reduces play and wear.

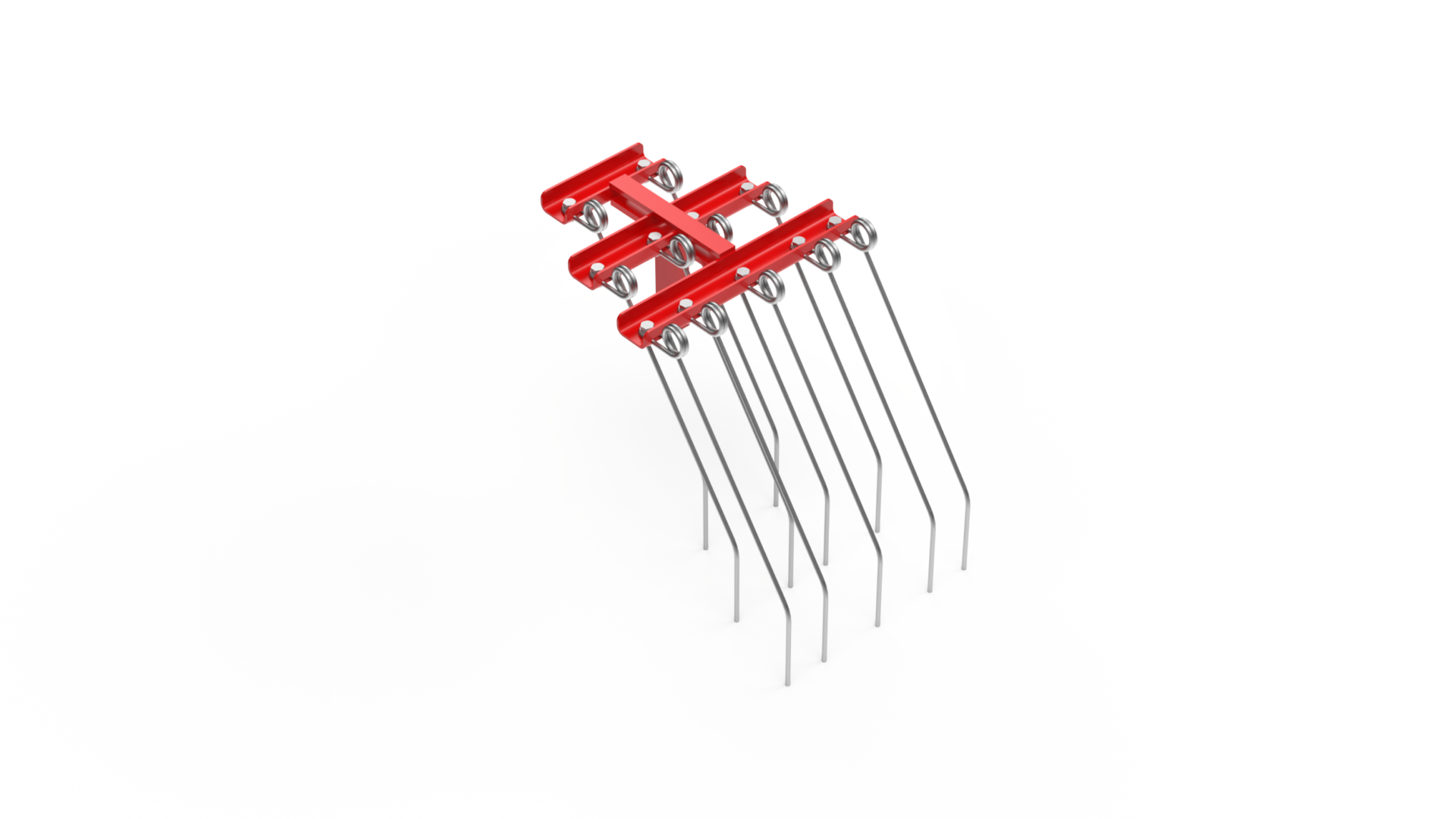

Our parallels are equipped as standard with a pressure control system, with each parallel being fitted with a cylinder. This pressure is adjustable from the tractor. This ensures that the hoeing elements can break through the top layer even on hardened soils and thus work optimally. The pressure control system actually divides the weight of the machine over the different parallels, allowing the force to be applied on the ground.

The pressure can be adjusted separately in the track of the tractor. Where the ground has more soil compactation, more force is needed. You can also easily adjust this via the display in the tractor.

Our parallels are clamped with a lever system around the beam, which is at 45°. This ensures a firmer clamping and the parallels can never come loose. This clamp can be released with one bolt, making it easy to move the parallel.

The hoeing elements are also clamped with a unique system: a clamping bolt pushes on an intermediate piece that clamps the hoeing elements firmly in the parallel holder via a leverage effect. This flat clamping prevents the hoeing element from becoming loose.

Different configurations

Thanks to the modular design of the Focas Heavy, different row distances are possible. The parallel can be equipped with different compositions of hoeing elements. Special about our parallel is the interchangeable tool holder, allowing different customized designs.

We have a wide range of hoeing elements. Think of angle share or slash share in Hardox, A-shaped shares in Hardox, ridgers on shares, ridgers for ridges and leeks, finger weeders, vibrating tines and even local burners,…

1 person to work large areas

Another advantage of the machine is you only need 1 person to weed large areas: someone at the wheel of the tractor. The camera control does the rest. Automatic and precise. Thanks to the ease of use of the camera control, only limited training is required, so just about anyone can handle this machine.

Suitable for organic farming

Due to the precise operation of the Focas Heavy, the hoeing elements can be adjusted more precisely. This way you remove even more weeds in a mechanical and reliable way and chemicals become unnecessary. This makes a hoeing machine suitable for organic farming.

The advantages

-

Hyper-precise thanks to reliable camera control

Hyper-precise thanks to reliable camera control -

1 machine for different soil types and crops

1 machine for different soil types and crops -

Clearance free parallel thanks to patented system

Clearance free parallel thanks to patented system -

Versatile and easily adjustable

Versatile and easily adjustable

Executions

Accessories

Are you interested in this FOCAS HEAVY?

Please fill out the information below and we will contact you as soon as possible.

Product form

"*" indicates required fields