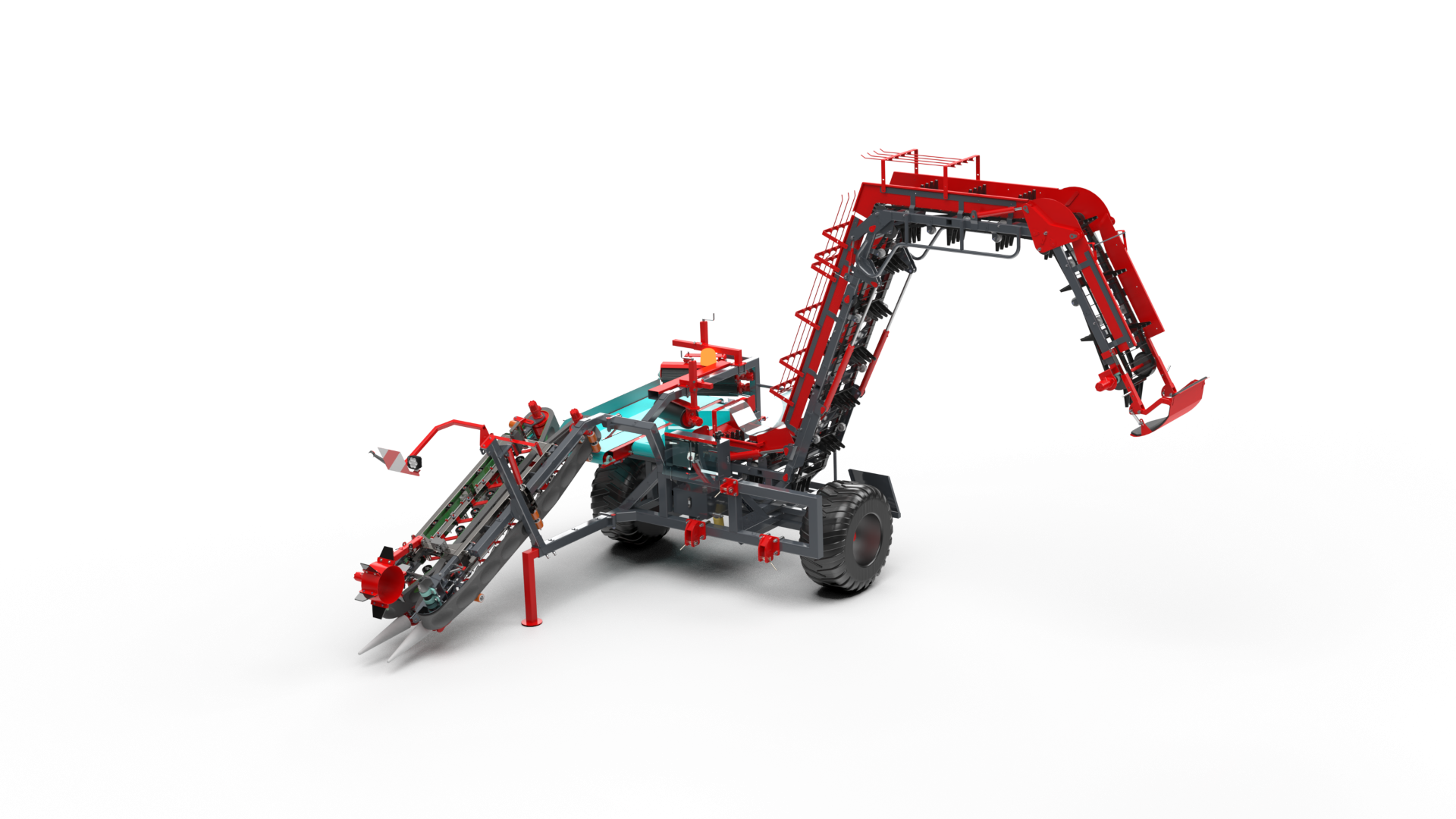

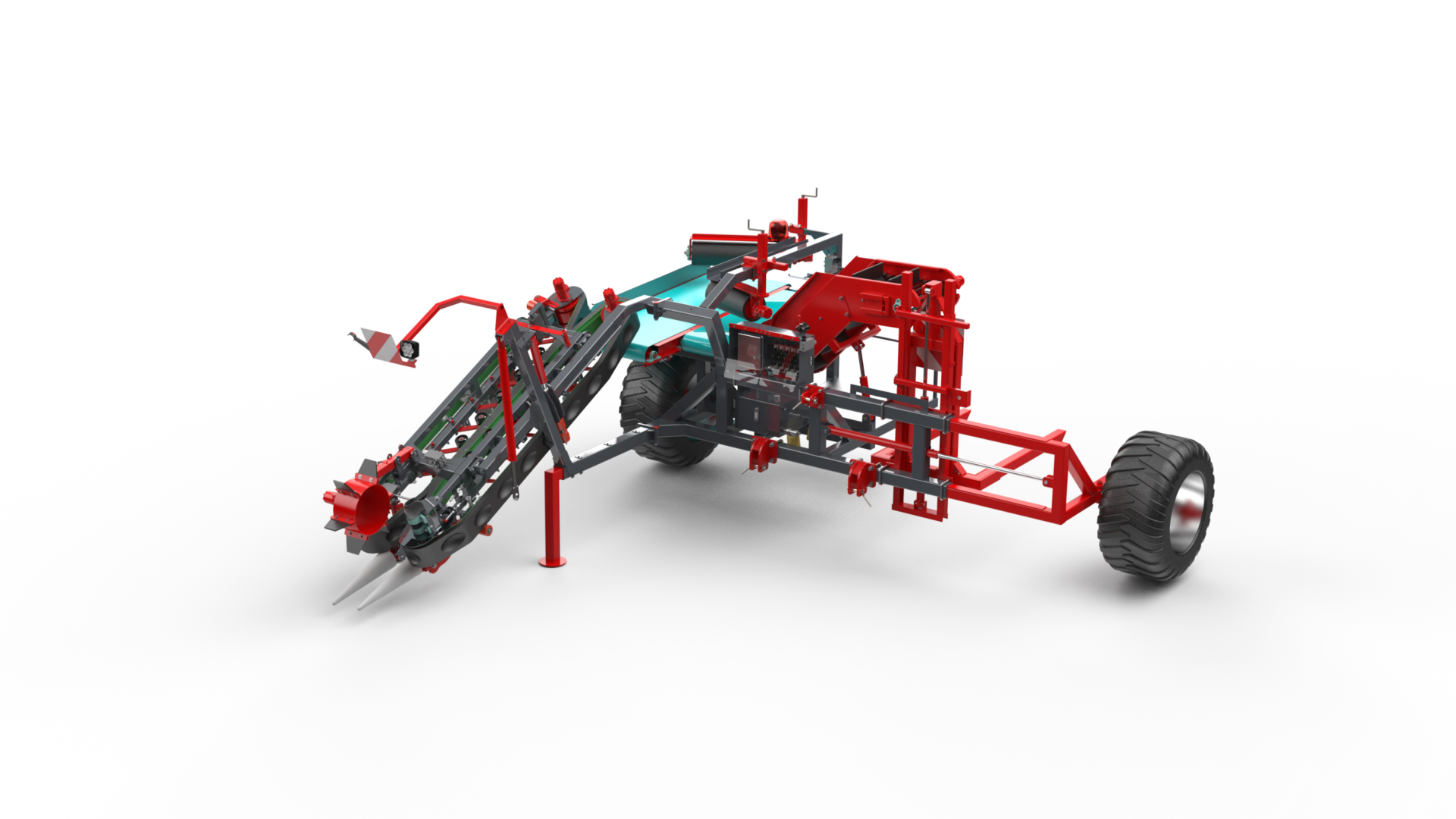

VITUS Brassica Industry

Cabbage harvester industry VITUS Brassica Industry

The VITUS Brassica Industry eliminates all manual work. While for the fresh market it is necessary to place the cabbage very gently (manually) in the containers, cabbages for industrial processing may be handled completely by machine. The cabbage harvester will automatically fill the wagon or container via a sieve web. Thanks to extensive automation, the VITUS Brassica Industry has an extremely high capacity. All the heavy work is taken over by the machine.

High capacity, high speed

The purpose of the industrial cabbage harvester is to remove as much cabbages as possible from the field in the shortest possible time. The cabbage harvester reaches speeds of up to 6 km/h. Even in challenging weather conditions, the machine does an excellent job. An additional aid is an infeed roller which gives the cabbages a push so they it is smoothly guided into the clip bindings.

Torpedoes, guide rods and soft clip bindings

The VITUS Brassica Industry takes hold of the cabbage on the side to protect the delicate top. Torpedoes raise the outer leaves of the cabbages, so the cabbages are protected in the clip bindings. The white plastic torpedoes and the guide rods work closely together. The first lifts the outer leaves of the cabbages, the second pulls the cabbages out of the ground. The clip bindings bring the cabbages towards the leaf removal system. The clip bindings are covered with a soft, durable cellular rubber and contain recesses into which the cabbages fit. Thanks to this combination, the cabbages are carefully clamped.

Perfectly cut

Halfway through the clip bindings, a unique stainless steel blade cuts the roots and the outer leaves of the cabbages. The combination of the torpedoes and guide rods ensures the cabbages end up straight and at the correct height in the clip bindings. The electrically height-adjustable blade can perfectly cut up to 99% of the root stump of the cabbages.

An extra help to cut the cabbages perfectly is an optional synchronisation of the speed of the clip bindings with the driving speed. This consists of 2 sensors, one on the running wheel of the harvester and a second on the clip bindings. In this way, the clip bindings are driven in a controlled manner and the cabbage enters the clip bindings perpendicularly, regardless of the driving speed. This way, the cabbages are guaranteed to be cut straight.

Ingenious leaf removal system

After the root and the outer leaves have been cut off, the cabbages enter the leaf removal system. This system consist of 2 conveyor belts with a light studded structure. The first conveyor belt is extra wide, so there is room for the outer leaves of the cabbage to fall open. Via a first push roller covered with soft rubber, the cabbages are guided towards a second conveyor belt with push roller. This guides the cabbages toward the sieve web, which then transports the cabbages to a container or trailer. The leaf removal system discharge the outer leaves on the field. In addition, the push rollers are adjustable in height and angle, which ensures optimal leaf discharge depending on the size of the cabbages. The push roller also removes loose leaves from the cabbages. The push rollers also remove loose leaves from the cabbages.

Automatic filling system

Finally, the sieve web automatically brings the cabbages to the container or trailer. The customer chooses the desired version of the sieve web according to the containers or trailers. The single box version has a forklift integrated into the machine, allowing it to pick up and deposit containers independently. There are 3 standard versions available for trailers. You can choose from a discharge height of 2.5m, 3.5m and 4m.

As an option for the trailers, we offer a rotating discharge conveyor. This way, the trailer can drive behind the machine to enter the field.

Quick return on investment

The heavy and repetitive work is taken over by the machine. The harvester requires a maximum of 2 people; someone to drive the tractor and optionally someone to check the cabbages. Thanks to the automation and therefore high capacity, the machine can save up to 15 workers.

Suitable for tough conditions

Even in fields with many weeds, the VITUS Brassica harvests the cabbages without any problems. The cabbage harvester also works optimally in wet conditions and with heavy soils. No part of the machine goes into the ground and the feed roller gives the cabbages a push to ensure smooth harvesting.

The advantages

-

Straight cut cabbages thanks to unique blade and clamping system

Straight cut cabbages thanks to unique blade and clamping system -

If taken manually, also suitable for fresh market

If taken manually, also suitable for fresh market -

Fully automatic harvesting

Fully automatic harvesting -

Quick return on investment

Quick return on investment -

High capacity

High capacity

Executions

Are you interested in this VITUS BRASSICA INDUSTRY?

Please fill out the information below and we will contact you as soon as possible.

Product form

"*" indicates required fields